Abstract

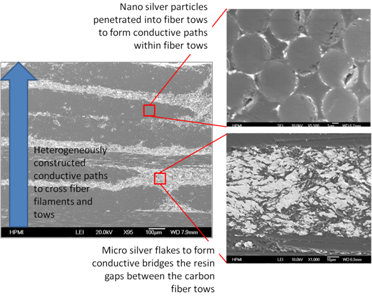

The objective of this project is to design and fabricate tailored thermal interface and continuous paths among nanoscale conductive fillers and filler/graphite fiber to promote effective phonon transport along through-thickness direction. The goal is to realize at least 100 fold increase of Kz from 0.2 to 20+ W/mK in graphite fiber composites. Meanwhile, we will study to construct chemical or electronic bonding between the fillers and graphite fibers to ensure adequate or improved interfacial bonding to improve mechanical properties. Different from current homogeneous dispersion of conductive fillers in composites, we will study and demonstrate effective approaches to construct heterogeneously phonon transport paths in composites through fiber surface deposition and utilizing heterogeneously structured high thermal conductive resin matrix materials. This project will develop and demonstrate the following three unique techniques:

- Electrochemical deposition of high aspect ratio nanoscale silver flakes to increase fiber surface roughness for improving interface bonding and load transfer, and also create adequate thermal transport contacts between fibers and silver flakes;

- Utilize commercial available or modified heterogeneously structured conductive resin matrix to fabricate composites;

- Study and optimize phase separation behavior of heterogeneously structured conductive filler phase to create preferred continuous phonon transport paths along through-thickness directions for high thermal conductivity.

Success of the project will lead to an affordable and scalable approach to make thermal conductivity (>20 W/mK) structural graphite fiber composites for potential Air Force and DoD applications. More importantly, these techniques and manufacturing processes are potentially easy to scale-up and low cost due to utilizing commercially available materials and route electrochemical deposition processes.