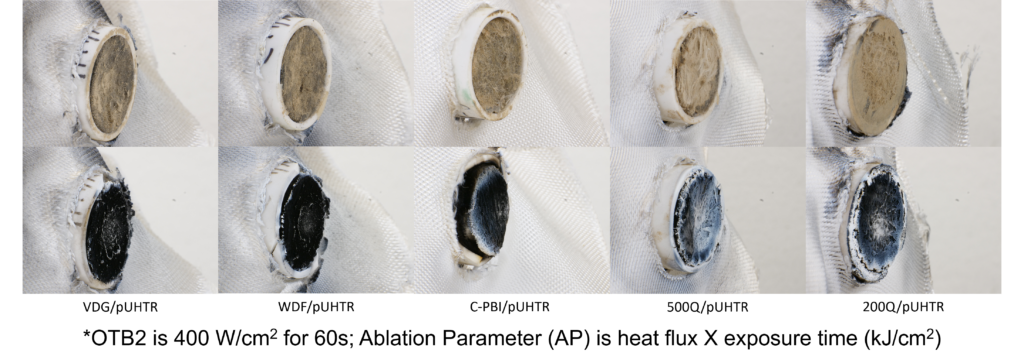

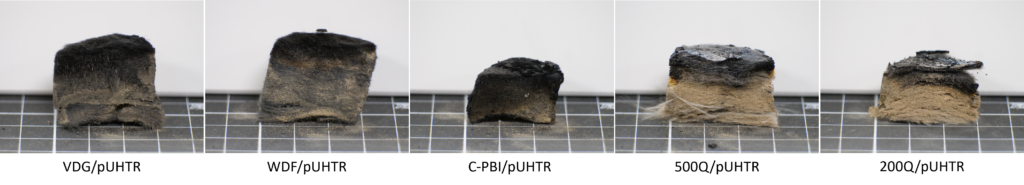

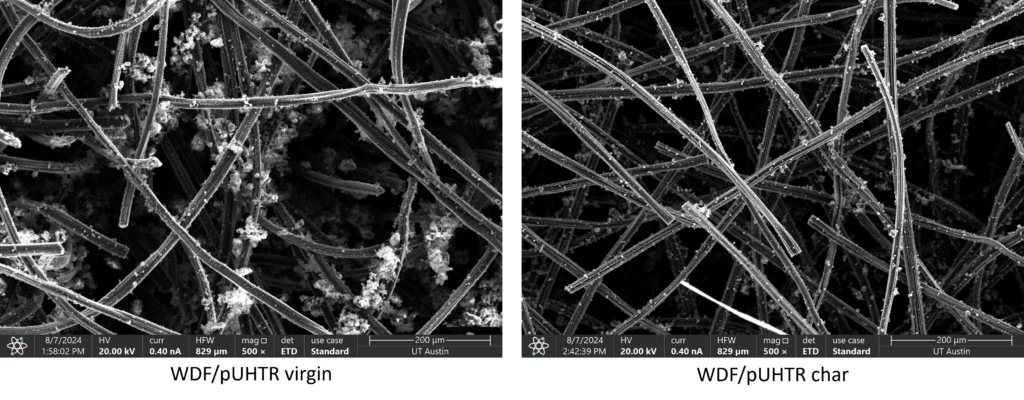

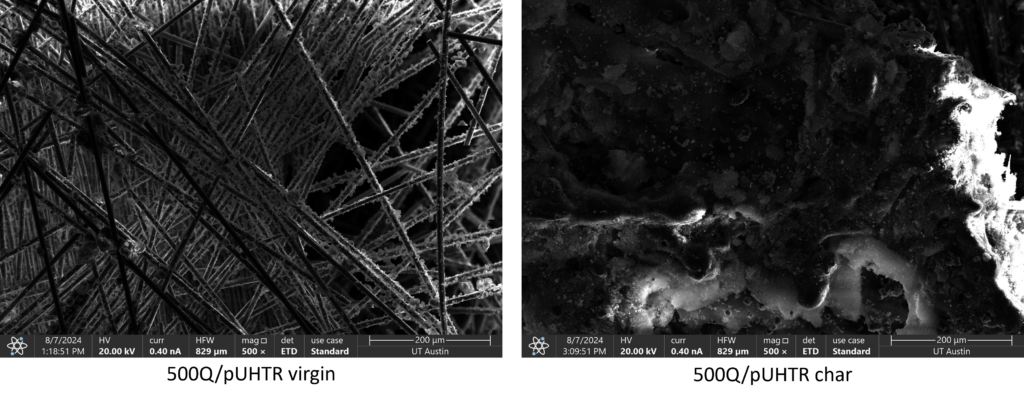

Development of high-performance ablative materials for thermal protection systems (TPS) has seen an increasing demand in the aerospace and defense industries. The present work utilizes the excellent thermal properties of Techneglas UHTR polysiloxane resin in its powdered form and mechanical properties of low-density felt materials in developing a novel family of low-density flexible ablators (LDFA) suitable for TPS applications where material flexibility and low density offers greater applications. In this study, the UHTR polysiloxane resin is powdered and homogenously infiltrated into various felt materials using a vacuum infiltration method. The resulting infiltrated LDFA composites are thoroughly investigated for thermal, flammability, and ablative properties. The LDFAs exhibit excellent flexibility, improved char yield, and the ability to withstand 400 W/cm2 for 60 seconds. Current work is being extended to more extreme ablative conditions of 600 W/cm2 for 60 seconds and 400 W/cm2 for 300 seconds combined with the analysis of mechanical properties of the ablated char.