About the Company

Koo & Associates International, Inc. (KAI) was incorporated in the State of Minnesota in 1994. KAI relocated to Austin, Texas in 1997 and was incorporated in the State of Texas in 2005. Our main focus has been in program and engineering management, with an earned reputation in defining requirements for customers, proposing solutions, executing programs, and delivering results. Its principal, Dr. Koo is highly-regarded in the technical field of materials science and is very active in professional societies, such as AIAA, JANNAF, MRS, and SAMPE. KAI maintains high-level of interaction and collaboration with industry, government, and academia. Currently KAI is specializing in the following research and development areas:

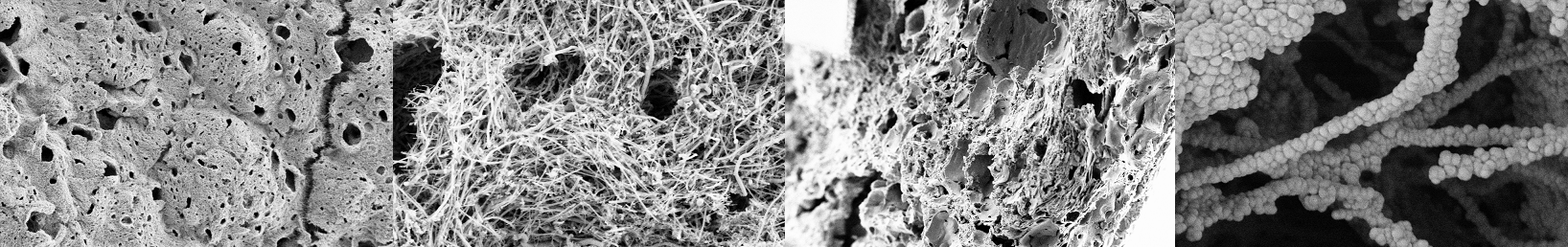

Ablation Research

- Solid rocket motor nozzle ablatives

- Experimental and numerical characterization of internal solid rocket motor insulation materials

- Functionally graded polyimide nanocomposite foams for space application

- Ablation and thermal characterization of missile/propulsion/re-entry ablative materials

- Ablation, thermal, and flammability properties of SiC fiber-reinforced ceramic matrix composites

- In-situ ablation recession and thermal sensor for thermal protection systems (TPS)

- Char strength sensors to evaluate polymer nanocomposite ablatives

- Material and thermal response modeling of ablatives

Flame Retardant Polymers Research

- Flame retardant polymers for selective laser sintering (SLS) in additive manufacturing (AM)

- Flame resistant fabrics/textiles via electro-spinning/melt-spinning

- Numerical modeling of polymer degradation kinetics

Conductive Polymers Research

- Electrically and thermally conductive polymers for selective laser sintering (SLS) in additive manufacturing (AM)

- Multifunctional cyanate ester-f-CNT nanocomposite impregnated with carbon fiber-reinforced composites

- Conductive textile threads

- High thermally conductive epoxy nanocomposite impregnated with graphite fiber-reinforced composites

- Thermal isolation coatings

Others

- Homopolar generator (HPG) welding to join the high performance bridge steel

- High temperature epoxy nanocomposite impregnated with glass fiber-reinforced composites for downhole drilling

- Nanostructured carbon/carbon composites